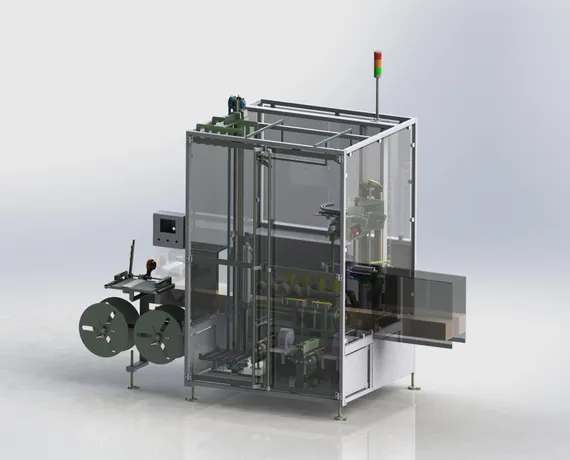

BLM sleeve applicator

Especially dedicated to shrink and stretch sleeves, BLM equipment offers the fastest stretch sleeve application on a linear platform.

Advantages

Advantages

- Unique Accu-shaped™ applicator head always matches container shapes

- Perfect placement of sleeves on square and rectangular containers

- Versatile: Capable of handling the widest range of sizes in the industry

- Ultra-rapid changeover (less than 15 minutes)

Technical characteristics

Technical characteristics

- Linear system: intermittent movement

- Mechanical application

- Unique design: with 2 or 4 pairs of stretchers to guarantee perfect sleeve positioning

- Allen Bradley platform

Abilities

Abilities

- Container size: 200 ml to 2.5 gallons

- Stackpak-multipack: Stretch sleeve (Conserves) (Food) at 40 CPM on BLM-50

- Twinpack stretch sleeve (cleaning product) at 30 CPM on BLM-30

- High-elasticity stretch sleeve (dairy products) at 50 CPM on BLM-50

- Stretch sleeve (chemical products) at 50 CPM on a BLM-75 with cold glue applicator