Why choose stretch sleeves?

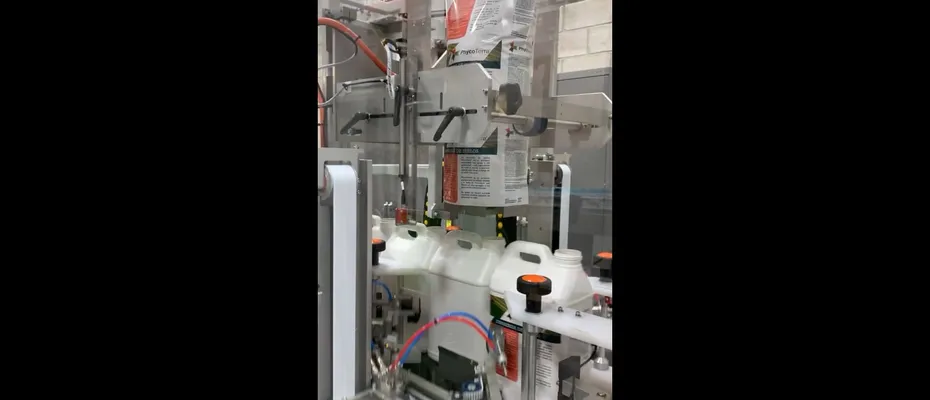

If you thought that packaging and respect for the environment did not go hand in hand, think again! CeltheQ will be happy to show you the opposite with stretch sleeves! Indeed, this technology, which has existed for more than thirty years, has many advantages in terms of personalized printing techniques, while combining the ecological aspect.

The stretchable PE sleeve can deform up to 30% for the same printing quality, which allows it to cover 360 degrees of the product while offering a so-called "partial" decoration on the shoulders of the product.

Practical Advantages

Decorative limitations are compensated for by numerous advantages including:

- Sleeving of fragile, heat-sensitive products

- Less energy consumption in terms of consumables, water and electricity

- Materials that are easy to detach and recycle (PET)

- Cold, clueless application

- Use of the Accu-shaped™ technique

- Uniform use of decoration and product grouping

- Flexibility in product shape and volume variations

- No in-line shrinkage or heat release required, making it compatible with fresh produce

- Applicable on empty containers: no need for mechanical stress on the walls when shrinking

We should also mention:

- High temperature resistance from -40C to +40C

- Compatibility with ATEX environments

- Light and minimal carbon footprint

- Transparency and brightness offering a lovely spectrum of vivid colours

| Stretch | Shrink | High-elasticity | |

|---|---|---|---|

| Tamper evident | X | X | |

| Recyclability | X | X | X |

| Energy savings | X | X |