Our equipment

CeltheQ offers various kinds of sleeve applicator equipment to meet your specific needs. Our products are designed to provide fast, accurate and efficient sleeve application while minimizing waste and production costs. We are committed to providing you the best possible sleeve application equipment to improve productivity and profitability.

Sleeve applicators

We are particularly proud of our innovative and unique sleeve application technology. Various models are available to meet your needs and respond to your activity sector. Our team of experts can provide you with the best recommendations.

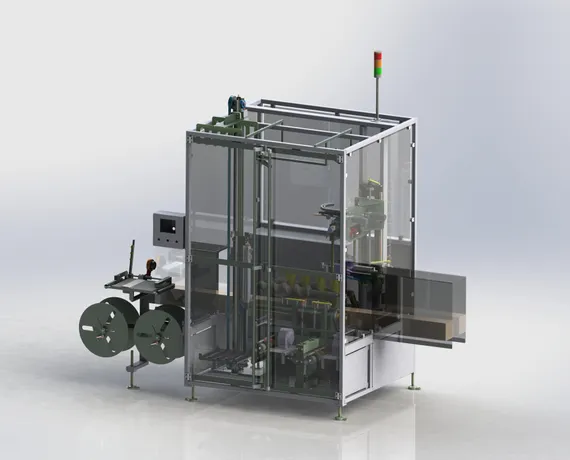

BLM sleeve applicator

Especially dedicated to shrink and stretch sleeves, BLM equipment offers the fastest stretch sleeve application on a linear platform.

Advantages

- Versatile: Capable of handling the widest range of sizes in the industry from 200 ml to 2.5 Gallon

- Ultra-rapid changeover (less than 15 minutes)

- Square, rectangular, oval round, empty or filed containers

Technical characteristics

- Linear system

- Mechanical application

- Unique design: with 2 or 4 pairs of stretchers to guarantee perfect sleeve positioning

- Allen Bradley platform

Abilities

- Container size: 200 ml to 2.5 gallons from 15 to 150 ppm

- Twinpack or multiple bundling

- Stackpak (vertical bundling)

- High-elasticity stretch sleeve

HC series sleeve applicator

Also dedicated to shrink and stretch sleeves, this equipment offers many advantages that guarantee an optimal return on investment without disrupting your existing production line.

Advantages

- High speed

- Unique Accu-shaped™ applicator head, that always matches container shapes

- Application capabilities for all types of sleeve labels: standard PE sleeves, shrink sleeves

- Best equipment for high-speed decoration lines and tamper evident complete decoration

- Application capability for thin sleeves as low as 20 microns

- Best applicator for large diameters and small heights for the HCL machine

- All-modular system: tool-free changeover (in less than 30 minutes with two operators)

- Double system: Application capability for shrink and stretch sleeves

- Best applicator for asymmetrical containers

Technical characteristics

CL Applicator

- Rotating system

- Various configurations depending on your line needs

- Multiple directions depending on your line needs

- Allen Bradley platform

- For dry, wet or condensation products

- Round and non-round containers

HCL Applicator

- Linear system

- Only oval rotating applicator on the market

- Allen Bradley platform

- Capable d’appliquer des manchons rétractables

- For dry, wet or condensation products

- Containers of all shapes

Abilities

- From 120 to 800 products per minute

- For labeling and bundling

- For standard stretch PE, high-elasticity PE, thin gauge film, shrink sleeve

Ultimate series sleeve applicator

Available only in Canada and South America, this applicator is recommended for heat shrink sleeves and offers various possibilities, especially in the food and pharmaceutical and industries.

For this category, two types of equipment are available:

Ultimate T:

- Best applicator for small products (batteries, pens, pharmaceutical products)

- Partial, complete or anti-tamper decoration

- Dry or wet containers

Ultimate M:

- Best machine for complete high-speed decoration (beverages, dairy products, food)

- Full body

- Dry containers

Advantages

- High speed

- Unique Accu-shaped™ applicator head

- Perfect placement

- Long-lasting Straight-Cut™ blades

- Labelling capability for virtually all consumer products: beverages, dairy products, household products and more

- Capacity: 150 ml. to 1.5 litres

- Speed: up to 500 CPM

Technical characteristics

- Linear system

- Unique applicator head

- Allen Bradley platform

Abilities

- Tamper-evident sleeves (pharmaceutical) at 220 CPM on T2-75/120

- Heat-shrink tubing (dairy products) at 100 CPM on M1-160/280

- Shrink tubing (juice) at 200 CPM on M2-100/300

- Heat-shrink tubing (water) at 300 CPM on M4-100/300

Shrink tunnels

This equipment is compatible with any shrink sleeve applicator.

TAR Series

Advantages

- Ambiance™ technology: Progressive shrinkage to improve the final appearance without stressing the sleeve

- Ramp Nozzle™ technology: Complete control of nozzle direction and distance from each side panel

- Energy efficiency: we use only the power needed for your specific application

- No thermal shock as the products shrink gently

Technical characteristics

- Modular system: TAR 1500 and TAR 3000 tunnel length depending on your line needs

Abilities

- Capacity: 200 ml. to 1 gallon

- TAR-1500 Ambiance™ Technology hot-air tunnel – OFF

- TAR-1500 Technology hot-air tunnel

TV series

Advantages

- Flex-Flow technology: Controls direction, angle, distance, and steam pressure from each five (5) duct panel side

- Best possible appearance for your product

Technical characteristics

- Filtration system to reduce humidity

- Modular system: TV 2000 and TV 3000 to mix and match according to your line needs

- Single and double shrink zone

Abilities

- Capacity: 200 ml. to 1 gallon

- TV-2000 steam tunnel

Parts quote form

We have exclusive parts available in inventory for immediate delivery.